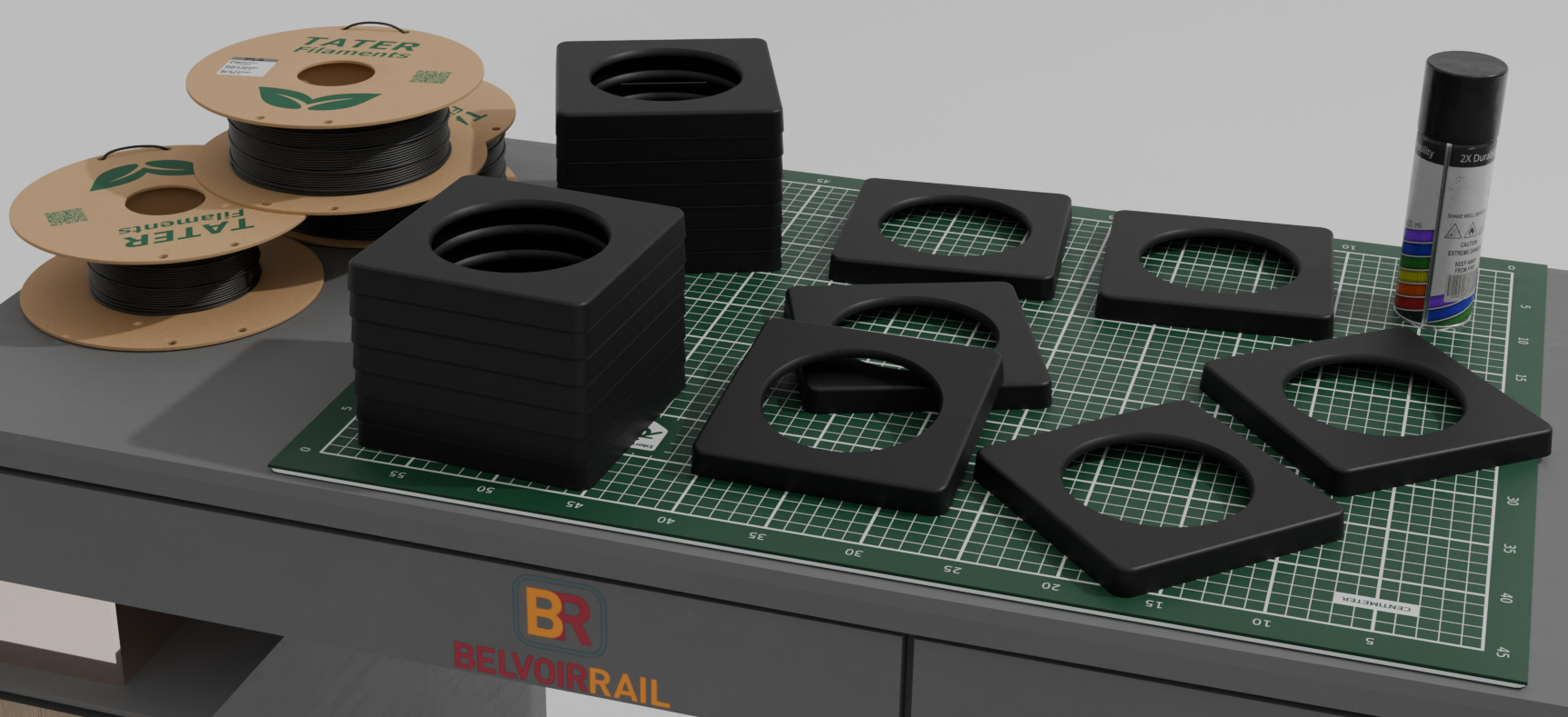

3D printing for rail and rolling stock. Guaranteed lifetime part availability, exact-fit replacements when you need them, and total obsolescence protection.

Tailored for rail

Belvoir Rail delivers advanced 3D printing solutions for the rail industry, ensuring lifetime part availability and protection against obsolescence.

We help operators reduce downtime and extend fleet life with rapid, on-demand production of high-quality, rail-approved components.

From interior fittings to exterior parts, our durable, cost-effective solutions keep your trains running safely, reliably, and efficiently.

Materials we offer

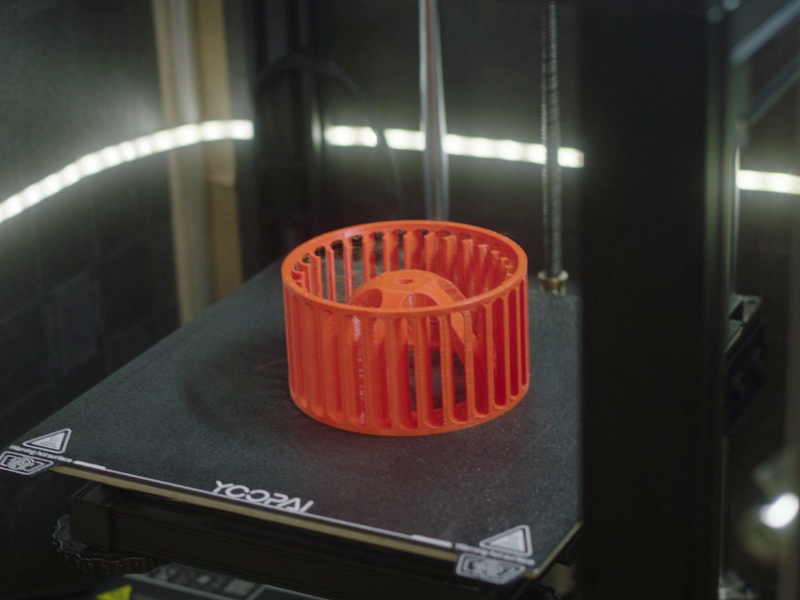

We offer a range of materials to match your technical and operational requirements:

- Engineering Plastics: PLA, PETG, ABS: Durable, reliable, and ideal for functional prototypes or end-use parts.

- Flexible: TPU: Rubber-like flexibility perfect for gaskets, seals, and shock-absorbing components.

- Metal: Added strength and thermal resistance for tougher, high-demand applications.

What we can print

Interior and Exterior Fittings

(Non-Structural)

- Seat components

- Covers and grilles

- Panels and casings

- Button housings and bezels

Benefits: Lightweight, design flexibility, cost-effective replacements, fast design iteration.

Maintenance and Replacement Parts

- Brackets and mounts

- Custom housings, boxes and bezels

- Tracks, clips and runners

Benefits: On-demand production, easier legacy part reproduction, custom integration of new technologies such as sensors and cameras.

Prototypes and Design Mocks

- Scale models and mock-ups

- Cab layout prototypes

- Functional prototypes for testing before full-scale manufacturing

Benefits: Quicker validation of designs, stakeholder engagement, ergonomics testing.

Benefits of 3D printing

|

Perfect Fit |

Parts built to your exact dimensions and fleet requirements |

|

End Obsolescence |

Recreate discontinued parts with ease |

|

Rapid Prototyping |

Quickly test and iterate new designs |

|

Fast Turnaround |

Speed up repair cycles and get trains back on track |

|

On-Demand Production |

Manufacture what you need, when you need it |

|

Small Batch Friendly |

No minimum order quantities needed |

|

No Tooling Costs |

Ideal for low-volume production and custom runs |

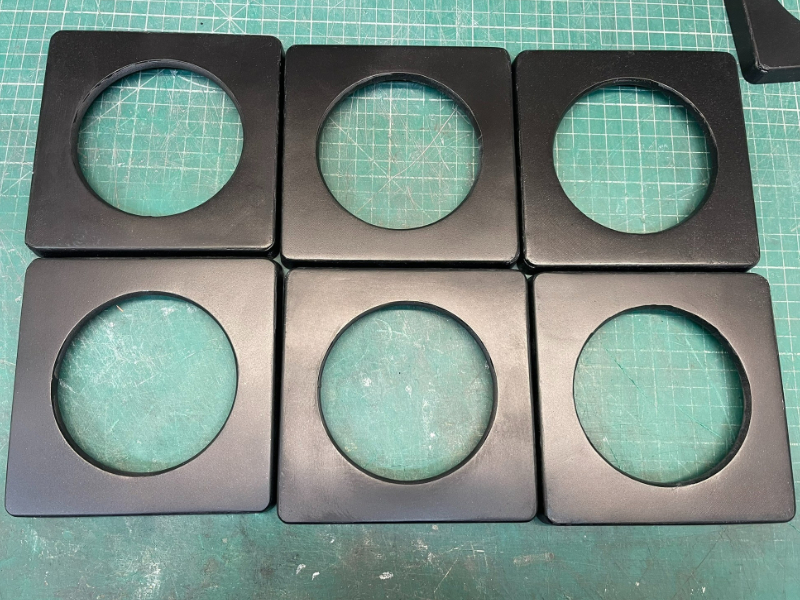

Case study

Fire boxes

The Challenge: A UK train operator faced a critical supply issue. Fire boxes for some of its older rolling stock had become obsolete, risking fleet compliance and safety. Replacing the parts using traditional manufacturing methods would have been prohibitively expensive and time-consuming.

Our Solution: Belvoir Rail reverse-engineered the part using 3D scanning and reproduced it in durable ABS. The replacement units were delivered rapidly at a significantly lower cost per part for the operator.

The Result: Trains returned to service faster with newly installed fire boxes. On-demand 3D printing replaced injection moulding, removing the need for expensive tooling and large minimum orders. Future replacements can now be produced quickly and affordably, with easy design updates when needed.

Struggling with delays, obsolete parts, or rising costs?

Let’s fix that. Discover how 3D printing can keep your fleet moving, faster and more affordably.