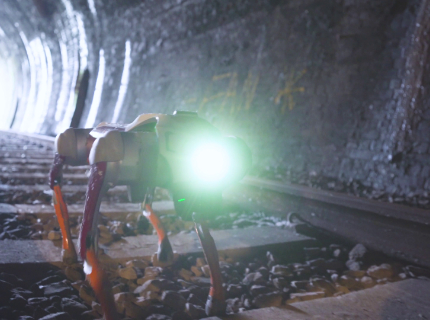

Quadruped robots with advanced sensors and AI provide safer, faster, and more precise rail inspections. Quickly detect issues, reduce downtime, and keep rail networks running smoothly.

A new standard in rail inspections

Less Risk. More Insight.

AI driven sensors take workers out of hazardous environments by handling inspections in high risk areas. They detect faults faster and more accurately than manual checks, improving safety and maintenance efficiency.

Key platforms and features

Go2

Detect cracks, misalignments, and track defects in real time

- Compact and lightweight: Easily deploys in tight or remote spaces.

- Up to 12kg Payload Capacity: Supports essential sensors

- High-Speed Mobility: Up to 3.7 m/s for fast deployment.

- Max 40°Climb Angle: Handles sloped surfaces with ease.

- Wide Angle 4D LIDAR: precision mapping, obstacle detection and automated navigation.

- Up to 4 hours battery life: Ideal for localised inspections.

- Cost-Effective and Scalable: Perfect for routine and smaller scale operations.

- Wheeled variant: options available

B2

Heavy Duty Inspection & Monitoring

- Rugged IP67 Design: Built for ballast, unstable surfaces and 45° slopes.

- Max 1.6m Jump Distance: Clears track gaps and small obstacles.

- High-Speed Mobility: Up to 6m/s for rapid deployment.

- High Payload Capacity: Supports 120kg standing, 40kg walking, allowing multiple advanced inspection tools.

- AI Powered Navigation: LIDAR, depth, and optical cameras for smart inspection.

- Extended Battery: 4–6 hours of continuous use.

- All weather ready: Operates from -20°C to 55°C.

- Powerful AI Processing: Real-time anomaly detection and data analysis.

- Wheeled variant: options available

Add on Sensors

Inspection equipment add-ons

- HD & 360° Cameras: For detailed visual inspections

- Thermal Imaging Sensors: Detect overheating components and track infrastructure issues.

- LiDAR Scanners: Provide detailed mapping of rail environments.

- Chemical Sensors: Detect hazardous leaks and gases.

Built for rail

Quadruped robots are built for mobility, intelligence, and reliability.

Predictive and Proactive Maintenance

- Early Fault Detection AI insights help prevent issues before they escalate.

- Minimised Failures Preventative repairs reduce downtime and costs.

Safety and Precision

- Risk-Free Inspections Robots handle dangerous tasks, keeping workers safe.

- Objective & Unbiased Data Accurate assessments, unaffected by weather or fatigue.

Efficiency and Real-Time Insights

- Faster Inspections High-precision results, delivered quickly.

- Automated Documentation No manual data entry, fewer errors and delays.

- Instant Data Real-time updates for immediate action.

Smarter Data Integration & AI Driven Insights

- Historical Analysis Track asset conditions for predict maintenance.

- Unified Platforms Eliminates data silos, improving collaboration.

Highly Durable technology

- Rugged & Reliable Handles extreme weather and tough conditions

- Reliable Power Management Long lasting batteries with quick swap options.

Solving Key Rail Inspection Challenges

Faster Inspections. Fewer Risks. Smarter Railways.

| Problem | Solution with Quadruped Robot |

|---|---|

| Risky & Hazardous Inspections | Reduces human exposure to dangerous environments and high risk tasks. |

| High Costs & Downtime | Minimises possessions and reduces operational costs. |

| Limited Accessibility | Reach tunnels, bridges, culverts, embankments and hard-to-access areas. |

| Human Error | Uses AI-driven, high-precision sensors for reliable, objective data collection. |

| Slow Manual Inspections | Increases speed and frequency of inspections. |

Get started

We make it easy to integrate robot dogs into your rail inspection strategy:

| Assessment | We’ll discuss your needs and recommend the right robotic solution | |

| Deployment | We’ll help set up and integrate the technology with your existing systems | |

| Training and Support | Our team provides hands-on training and ongoing technical support |